ProductsYour are here: Home >> Products >> filter element

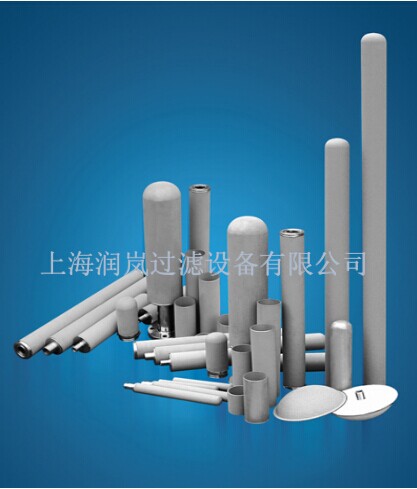

Titanium filter element Details:

A: the main performance

Titanium filter (including tube type and plate type) with high purity titanium powder industry (99.4%) as raw materials, after the screening, after cold isostatic pressing, micro filter element with high temperature and high vacuum sintering. Thus titanium filter plate composed of the high-tech materials and special molding technology, it has a unique performance:

1, uniform pore size and pore shape stability, high separation efficiency.

2, high porosity, high permeability, low filtration resistance efficiency.

3, high temperature, in 280 degrees (wet) under normal use.

4, good chemical stability, acid and alkali resistance (PH2-12), has antioxidant properties.

5, no particles fall off, not to make the solution form two pollution, comply with food hygiene requirements and pharmaceutical GMP.

6, good mechanical properties, low differential pressure, flow rate, filter press can be filtered, simple operation.

7, anti microbial ability, do not interact with microorganisms.

8, on-line regeneration, easy cleaning, long service life (usually a membrane filter several times)

9, good forming process, welding length up to 1000 mm without overall.

10, no magnetic non-toxic, and with human tissue and blood has good compatibility, is widely used in the pharmaceutical industry, food industry and water treatment industrial.

Two, the main technical parameters

Accuracy: 0.22 M-100 M

Length: 5 ", 10", 20 ", 30", 40"

Od: O 60mm

Filter interface: screw type (M20, M30, M36, M42), type 222, type 226

Maximum working temperature: 300 degrees

The maximum pressure: 0.6Mpa

Water flow: > 600L/H (10 ")

Three, titanium filter application areas

Titanium filter core to its unique performance can be widely used in the pharmaceutical industry, water treatment industry, food industry, biological engineering, chemical industry, petroleum chemical industry, metallurgical industry and gas purification field is a kind of new filter material with broad prospects for development of the. Typical uses include: 1, pharmaceutical industry big transfusion, injection, drop eye drops, oral liquid concentrated with a link in the removal of carbon filter and diluted with a link in the terminal filtration of security filtering.

2, in the production process of raw materials in addition to impurities filter, material removal of carbon filter and fine filter.

3, water treatment works for a security filter thing UF RO, EDI system, odor after sterilization filtration and ozone aeration.

4, food and beverage drinks, fruit juice, wine, beer, vegetable oil, mineral water, soy sauce, vinegar clarification filtration.

5, chemical industry liquid products, liquid raw materials, pharmaceutical intermediates de carbon filtration and fine filtration, ultrafine crystal catalyst, filtering and recovering, resin and desorption of precision filtration and heat conducting oil, material impurity filtration, gas catalytic purification and so on.

6, oilfield reinjection water filtration, reverse osmosis desalination security filtering field.

7, the high temperature of the dye industry to remove carbon, remove the white cheese filter.

8, gas purification of steam, compressed air, catalyst filtration.

Four, titanium filter to use matters needing attention

1, titanium filter belongs to consumables, although than other filtering components and durable, but in the process of cleaning and disassembly should pay attention not to scratch and touch, smashing, throwing etc. phenomenon, to prevent human injury. The use of tools on the surface of the filter is strictly prohibited.

2, in general, the filtrate from the filter outside the filter, do not advocate the reverse filter.

3, filter, slowly to the required pressure of work, is strictly prohibited to open the valve quickly quickly.

4, the working pressure is less than 0.45MPa. When the pressure exceeds 0.45MPa, in a timely manner with clean air or clean liquid backblowing online backwashing, anti blowing pressure is less than 0.6MPa.

5, titanium filter in anti blowing and backwashing, generally the first to use pure gas blowback, anti blowing pressure is 1.5 times the working pressure, after each reverse blowing time 3-5 seconds, repeated operation of 4-6 times with clean liquid backwashing, backwashing 3-5 minutes, operation 2-3 times.

6, such as the filter core online anti blow after washing, the pressure loss is still more serious, should be promptly removed for cleaning.

Five, the titanium filter cleaning method

According to the chemical properties of titanium filter pollution and pollutants and combined with the materialization of titanium, can be used in physical and chemical methods for cleaning regeneration. Physical methods mainly use: clean liquid, clean gas blowback recoil and ultrasonic cleaning method. Chemical methods are mainly used: dilute acid and alkali, oxidizing agent, surfactant and enzyme cleaning agent. The above methods can be used alternately. According to the common application of several kinds of cleaning methods are as follows:

Carbon filter off 1, pharmaceutical and chemical industry, to backblowing and backwashing method and the best combination of the effect of ultrasonic cleaning is often used.

2, the water industry, because the surface of the filter core interception for the non water soluble salts and oxides, usually with 5% nitric acid, without ultrasonic cleaning, you can achieve the cleaning effect.

3, liquid filtration, according to the chemical properties of pollutants, the following methods were used for cleaning:

(1): analysis of pure alkali washing solution for 30-60 minutes with 3-5% sodium hydroxide, temperature of 40 degrees, the best in ultrasonic cleaning machines. After soaking with filtered deionized water or water for injection and rushed to neutral, the measured conductivity. With pure air dry pressure is greater than or equal to 0.4MPa.

(2): pickling with nitric acid solution for 5% 8 hours or more, the temperature is about 40 degrees. The best in ultrasonic cleaning machines. After soaking with filtered deionized water or water for injection and washing to neutral, lateral conductivity. With pure air dry pressure is greater than or equal to 0.4MPa.

(3) the organic pollution can be cleaned with surface active agent, cell debris contaminated with enzyme cleaning system effect is more ideal (food and beverage with high concentration of citric acid cleaning).

(4) the above methods can be used alone, also can match each other alternately. If the conditions.

Titanium filter (including tube type and plate type) with high purity titanium powder industry (99.4%) as raw materials, after the screening, after cold isostatic pressing, micro filter element with high temperature and high vacuum sintering. Thus titanium filter plate composed of the high-tech materials and special molding technology, it has a unique performance:

1, uniform pore size and pore shape stability, high separation efficiency.

2, high porosity, high permeability, low filtration resistance efficiency.

3, high temperature, in 280 degrees (wet) under normal use.

4, good chemical stability, acid and alkali resistance (PH2-12), has antioxidant properties.

5, no particles fall off, not to make the solution form two pollution, comply with food hygiene requirements and pharmaceutical GMP.

6, good mechanical properties, low differential pressure, flow rate, filter press can be filtered, simple operation.

7, anti microbial ability, do not interact with microorganisms.

8, on-line regeneration, easy cleaning, long service life (usually a membrane filter several times)

9, good forming process, welding length up to 1000 mm without overall.

10, no magnetic non-toxic, and with human tissue and blood has good compatibility, is widely used in the pharmaceutical industry, food industry and water treatment industrial.

Two, the main technical parameters

Accuracy: 0.22 M-100 M

Length: 5 ", 10", 20 ", 30", 40"

Od: O 60mm

Filter interface: screw type (M20, M30, M36, M42), type 222, type 226

Maximum working temperature: 300 degrees

The maximum pressure: 0.6Mpa

Water flow: > 600L/H (10 ")

Three, titanium filter application areas

Titanium filter core to its unique performance can be widely used in the pharmaceutical industry, water treatment industry, food industry, biological engineering, chemical industry, petroleum chemical industry, metallurgical industry and gas purification field is a kind of new filter material with broad prospects for development of the. Typical uses include: 1, pharmaceutical industry big transfusion, injection, drop eye drops, oral liquid concentrated with a link in the removal of carbon filter and diluted with a link in the terminal filtration of security filtering.

2, in the production process of raw materials in addition to impurities filter, material removal of carbon filter and fine filter.

3, water treatment works for a security filter thing UF RO, EDI system, odor after sterilization filtration and ozone aeration.

4, food and beverage drinks, fruit juice, wine, beer, vegetable oil, mineral water, soy sauce, vinegar clarification filtration.

5, chemical industry liquid products, liquid raw materials, pharmaceutical intermediates de carbon filtration and fine filtration, ultrafine crystal catalyst, filtering and recovering, resin and desorption of precision filtration and heat conducting oil, material impurity filtration, gas catalytic purification and so on.

6, oilfield reinjection water filtration, reverse osmosis desalination security filtering field.

7, the high temperature of the dye industry to remove carbon, remove the white cheese filter.

8, gas purification of steam, compressed air, catalyst filtration.

Four, titanium filter to use matters needing attention

1, titanium filter belongs to consumables, although than other filtering components and durable, but in the process of cleaning and disassembly should pay attention not to scratch and touch, smashing, throwing etc. phenomenon, to prevent human injury. The use of tools on the surface of the filter is strictly prohibited.

2, in general, the filtrate from the filter outside the filter, do not advocate the reverse filter.

3, filter, slowly to the required pressure of work, is strictly prohibited to open the valve quickly quickly.

4, the working pressure is less than 0.45MPa. When the pressure exceeds 0.45MPa, in a timely manner with clean air or clean liquid backblowing online backwashing, anti blowing pressure is less than 0.6MPa.

5, titanium filter in anti blowing and backwashing, generally the first to use pure gas blowback, anti blowing pressure is 1.5 times the working pressure, after each reverse blowing time 3-5 seconds, repeated operation of 4-6 times with clean liquid backwashing, backwashing 3-5 minutes, operation 2-3 times.

6, such as the filter core online anti blow after washing, the pressure loss is still more serious, should be promptly removed for cleaning.

Five, the titanium filter cleaning method

According to the chemical properties of titanium filter pollution and pollutants and combined with the materialization of titanium, can be used in physical and chemical methods for cleaning regeneration. Physical methods mainly use: clean liquid, clean gas blowback recoil and ultrasonic cleaning method. Chemical methods are mainly used: dilute acid and alkali, oxidizing agent, surfactant and enzyme cleaning agent. The above methods can be used alternately. According to the common application of several kinds of cleaning methods are as follows:

Carbon filter off 1, pharmaceutical and chemical industry, to backblowing and backwashing method and the best combination of the effect of ultrasonic cleaning is often used.

2, the water industry, because the surface of the filter core interception for the non water soluble salts and oxides, usually with 5% nitric acid, without ultrasonic cleaning, you can achieve the cleaning effect.

3, liquid filtration, according to the chemical properties of pollutants, the following methods were used for cleaning:

(1): analysis of pure alkali washing solution for 30-60 minutes with 3-5% sodium hydroxide, temperature of 40 degrees, the best in ultrasonic cleaning machines. After soaking with filtered deionized water or water for injection and rushed to neutral, the measured conductivity. With pure air dry pressure is greater than or equal to 0.4MPa.

(2): pickling with nitric acid solution for 5% 8 hours or more, the temperature is about 40 degrees. The best in ultrasonic cleaning machines. After soaking with filtered deionized water or water for injection and washing to neutral, lateral conductivity. With pure air dry pressure is greater than or equal to 0.4MPa.

(3) the organic pollution can be cleaned with surface active agent, cell debris contaminated with enzyme cleaning system effect is more ideal (food and beverage with high concentration of citric acid cleaning).

(4) the above methods can be used alone, also can match each other alternately. If the conditions.